From the beginning of humanity until now, we have managed to create our world through our hard work and creativity. While we have made things easier to do, our creativity and imagination have been limited until the beginning of generative design.

With many new tools and applications released, freelance generative designers take advantage of innovative technologies that arise day by day.

Overall, generative design uses AI and other technologies to create new levels of architecture. In short, it integrates with many design solutions in order to create new development projects.

Well, now, let’s get to the best generative design applications you can use. Here are some of the best generative design applications you can use for your freelance work.

Top 6 generative design applications

Generative design provides you with unique, powerful tools for creating solutions associated with each application. Here, we will look at how generative design is used to create high-performance products that freelance architects and engineers can use.

1. Topology optimization & 3D printing

nTopology is considered one of the best generative design platforms for developing high-performance products. The platform is well known for its Topology optimization term and its generative design to 3D printing.

Topology optimization is a structural optimization technique firmly used for engineering concept design purposes. It is a potent design tool used for engineering and is excellent in reducing manufacturing costs and overall part weight.

In general, topology optimization is used in the early design process to generate new concept design candidates, reduce manufacturing costs, weight, material usage, and even assist with optimization problems regarding parts with a high stiffness-to-weight ratio.

Let’s not forget that the nTopology platform also bought generative designs for 3D printing. 3D printing is outstanding because it is a new technology that allows structure which was previously stated as impossible. This includes reduced weight, interior lattices, and even complex parts that are made in a single operation rather than assembled together. So, what does this platform solve?

The nTop platform can import CAD designs and then convert them to a field representation. After this is done, many special operations can be performed using separate tools.

What is so good about the platform is its ability to handle enormous 3D models that would ultimately destroy other systems. For example, a large radiator surface on other platforms is challenging to do, but it is easy on the nTop platform.

2. Thermal management

Cold plates, heat sinks, and exchangers are the main devices that transfer heat through conduction from a fluid and into a cooling medium. Thermal management systems are essential for engineering products to function since they improve their overall reliability and performance and ensure that their operation is entirely safe.

You may ask how effective the heat transfer is? This all depends on how great the surface area is in contact with the cooling medium. The size of the pump is also a great performance indicator that is determined by the pressure drop in a liquid-based cooling system.

Additionally, lattices provide an incredibly large surface area within a compact size. TPMS structures are usually used for liquid cooling since they can separate the flow into two different areas.

Generative design is the only solution to optimize highly complex geometries. In order to evaluate the performance of all of these advanced structures, an automated geometry generation that powers a simulation-driven workflow is needed. This is the only way to help a freelance engineer determine which geometry fulfills all of the design requirements for a specific application.

Thermal management is a generative design application primarily used in the aerospace, consumer products, and automotive industry. Its main advantages are:

- Minimizing pressure drop

- Reducing weight and volume

- Maximizing the surface area

3. Lightweighting

One of the top applications of a generative design is weight reduction, aka lightweight. Lightweighting is used for two main purposes, and those are:

- Reducing weight to increase performance

- Reducing weight to lower overall manufacturing costs

Weight reduction for increased performance is mainly used for automotive and aerospace applications. For example, less weight in cars will also decrease fuel consumption and vise versa.

Manufacturing costs are usually lowered when fewer or lighter materials are used, including industrial 3D printing, casting, and even injection molding. In these cases, lighter designs are usually achieved by substituting solid structures with lattices or even wholly removing solid structures.

The most common generative design tools used in lightweight are topology optimization and lattice structures. The main benefits of using lightweight are:

- Improving the efficiency of energy use

- Reducing overall manufacturing costs

- Improving product performance

The most common industries where lightweight application is used are the medical device, aerospace, and automotive industries.

4. The TAMU chair and Airbus

TAMU chair

Patrick Jouin, a French designer, revealed a TAMU chair prototype during the Milan design week. What is so special about the TAMU chair is that it can fold and consume less material. Solidwork was initially used to create the TAMU chair design and is supported by Dassault systems. Additionally, Dassault systems provide Patrick Jouin with resources through a 3D collaborative platform.

Airbus

The Airbus was created with the help of Fusion 360, which used a generative design to create an airplane cabin compartment. 45% of the overall weight was reduced by separating the gallery and passenger cabin with the help of a bionic pattern.

For airbus, this is a huge achievement because a weight reduction also means reducing fuel costs. In short, with a huge weight reduction, the airbus lowered overall fuel costs in the long term.

5. General Motors

General Motors managed to use generative design to compose eight parts into one, reducing the overall weight of the vehicles and increasing performance. Additionally, they also reduced the seat belt bracket weight and improved its total strength.

Generally speaking, traditional tools are relatively expensive and have no flexibility, making conducting experiments costly. Alternatively, generative design solves this problem by lowering manufacturing costs and supporting unlimited design solutions.

The reduced weight and re-design of the seat bracket in GM vehicles were built using generative-design technology with Fusion 360 and through a collaboration with Autodesk. If we use the traditional method of building a seat bracket, we will need to use eight parts, but the software managed to offer over 150 other designs that can be used within the vehicle. This is how they managed to develop a single stainless-steel piece instead of using eight of them.

So now, with all of these innovations made through the use of generative designs, the GM vehicle is 40% lighter than it used to be and has a 20% stronger seat bracket.

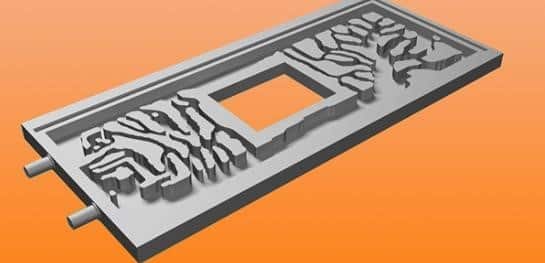

6. Architectural materials

If we talk about unique applications of generative design, then architectural materials are one of them. Architectural materials are a class of materials with an optimized topology used to achieve special functions.

Architectural materials have a customizable material response and are composed of complex lattice structures.

With the use of this material, you can enhance a part’s thermal, electromagnetic, and structural characteristics without changing the outer shape of the original design.

The flexibility architectural materials give you isn’t found anywhere else, as they allow you to change the product’s behavior without changing the manufacturing material used and only changing its digital design.

So, freelance engineers will use architectural materials by using digital materials and then applying them to products through field-driven design methods, customizing the product based on the user’s needs.

Architectural materials are usually used in the automotive, medical device industry, and consumer products. Their main benefits are:

- Customized products based on user’s needs

- Protective foams that are 3D printed

- Medical devices which are biocompatible

Wrapping it up

Well, that’s about it for this article. Hopefully, now, you have a better understanding of which are the best generative design applications you can use. Remember, generative design is used to make things more simple and compose many things into one.

This article goes into an in-depth review of what are the most popular generative design applications and how they are applied in real-life situations. We recommend you read through each of the generative design applications and see how you can use them in your own work as a freelance engineer or architect.

Use the technical resources you have to make the best out of your work. After all, generative design is used to make your life easier and your products better.